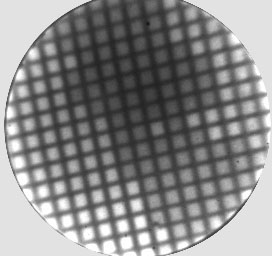

The image shows the domain pattern in a lithographically patterned polycrystalline Co triangular microstructure of 30 nm thickness on silicon. The magnetization reversal behavior of such microstructures can be followed with the PEEM by applying short magnetic field pulses between the acquisition of domain images.

White contrast means the magnetization vector is pointing towards the top of the image, dark contrast means it is pointing towards the bottom. Intermediate grayscales indicate horizontal magnetization directions. Field of view: 55 μm.See a QuickTime Movie (300 kB) of the magnetization reversal of these triangular microstructures (needs QuickTime Player).

These studies were

performed at SPring-8 in

Japan in collaboration with S. Imada and S. Suga,

Osaka University.

Publication: Japanese

Journal of Applied Physics 39, L585 (2000).